Alternator belts

This is a brief history of the alternator belts used on Oilhead boxers and the differences in how they are maintained. These models (R1100RS through the present) are the only ones with such belts; K and F series bikes have direct-drive alternators without belts. For reference, the Oilheads (R1100, R1150, R1200C) came with 40A or 50A alternators, and the Hexheads (R1200GS and later) come with 40A or 55A alternators.

Whereas adjusting similar belts on cars might come down to feel, the important point here is that there are absolute specifications for tensioning these belts. There is no need to use any kind of personal judgement on how tight or loose the belt should be.

There are basically two systems:

Poly V belt, a traditional cord-reinforced rubber belt used only on Oilheads (1993 through 2003 50A alternators, and all 40A alternators*). On early bikes the replacement interval was 24,000 miles; later it was increased to 36,000. Starting with the R1150 models, a re-tensioning after 6000 miles was added to the service schedule. This means the belt is re-tensioned at 6000 miles, replaced at 36,000, re-tensioned at 42,000, etc. This requirement was not retroactive to the earlier bikes.

ELAST, a stretchy belt introduced in July 2003 (2004 models). This was used with '04 and later 50A alternators and all Hexhead alternators. True to its name, this is an elastic belt, which is stretched to a predetermined length. The elasticity provides the tension. On the 50A and 55A models using this belt, a freewheeling pulley on the alternator reduces the belt load.** By 'freewheeling' I mean that it works just like a bicycle; the pulley will turn the alternator in the normal direction, but if the pulley slows down, as it does in the course of normal engine vibration, the alternator will continue to spin if conditions permit. This eliminates all of the 'backward' loading on the belt. Since the distance between the pulleys doesn't change, there is no need to re-tension this belt during its life.

Poly V: 4PK611, BMW part 12 31 1 341 779

ELAST: 4PK592, '04-on Oilheads and early Hexheads, BMW part 12 31 7 681 841

ELAST: 4PK582, R12RT/Adv, BMW part 12 31 7 690 571 11 31 8 528 385

Adjuster for Poly V belts: 83 30 0 401 699

Adjuster for Oilhead ELAST belts: 83 30 0 402 386

Poly V Adjustment

The Poly V belt is tensioned using a toothed adjuster which is part of the lower left mounting bolt. All three fasteners are loosened, then the adjusting bolt is turned to lift the alternator. When there is 8 Nm torque on the bolt, the three fasteners are tightened.

When the R1150RS was introduced, changes to the wiring harness made it difficult to access the head of the adjuster bolt, so a tool was created to torque this bolt from the threaded end (in front). This relatively inexpensive tool is little more than a nut with a closed end and a spring; it threads over the end of the bolt until it bottoms out, then can be used to turn the bolt. It can be used on all bikes with Poly V belts.

On some bikes, the powdercoat finish on the alternator mounting bracket softens and flows around some of the mounting bolts. This can block the motion of the alternator and alter the torque reading. I scrape the ridges of excess powdercoat away with a razor blade.

ELAST tensioning

The ELAST belt is not tightened to a particular adjuster torque or belt tension, but rather it is set to a fixed length. This confuses many people with late Oilheads for two reasons: BMW never updated the repair manual that was sold to owners, and the old adjuster mechanism is still present on the bikes although it is no longer used. The change to the service procedure was only published in a Service Bulletin which went to the dealerships.

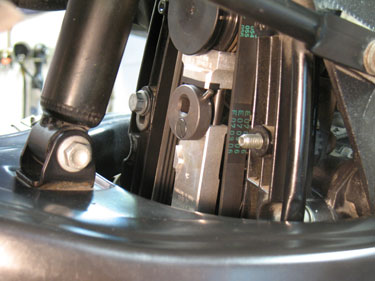

The old adjuster parts are still there on the 1150 because they hold that corner of the alternator to the bike. Consequently, the alternator is still free to slide up and down, and this is how the new belt is installed. But when it comes time to tighten the belt, the two pulleys are pushed apart to a preset distance using a special tool, then the alternator is bolted down tight. At no point is there any assessment of tension. Although the tool shown in the picture is handy, any method of spacing the pulleys properly (116mm between pulley flanges) will accomplish the goal.

Hexhead R1200 models

All of these models use one of two ELAST belts, and the alternator is simply bolted to the bike without any provision for adjustability. The belt is 'walked' on and off as the engine is rotated using a special tool. To facilitate this, the lower (drive) pulley does not have a flange on the front edge as the earlier ones do.

In general, the early models (GS, R, S, ST, HP2 Enduro and Megamoto) use the PK592 ELAST belt like the later Oilheads did, with a 60A Denso alternator* although the R1200RT and the R1200GS Adventure used a 55A Bosch alternator and a PK582 belt from the beginning. All subsequent models and facelifts (R and RT 2010-on, GS and Adventure 2008-on, R nineT, HP2 Sport) used the PK582 with a variety of alternators and a different lower pulley.

* except the R1200ST which had a different alternator

The '90° rule'

You'll see this passed around from time to time. The idea is that by twisting the belt with your fingers, you'll know the tension is correct because it gets harder to twist after 90° of twist. This is simply bad advice to give or follow, for someone who is using that as their only gauge, as the belt will exhibit those characteristics throughout a wide tension range (try it with an inexperienced person at 4 Nm and 12 Nm if you want to see for yourself). The amount of 'easy twist' at a given belt tension will vary with the free length of belt, belt construction, belt width and other factors which are somehow deemed irrelevant when this rule is passed around.

* Non-ABS bikes were usually equipped with 40A alternators rather than the 50A ones.

** One exception is the R1200ST, with a 55A alternator but lacking the frewheeling pulley.